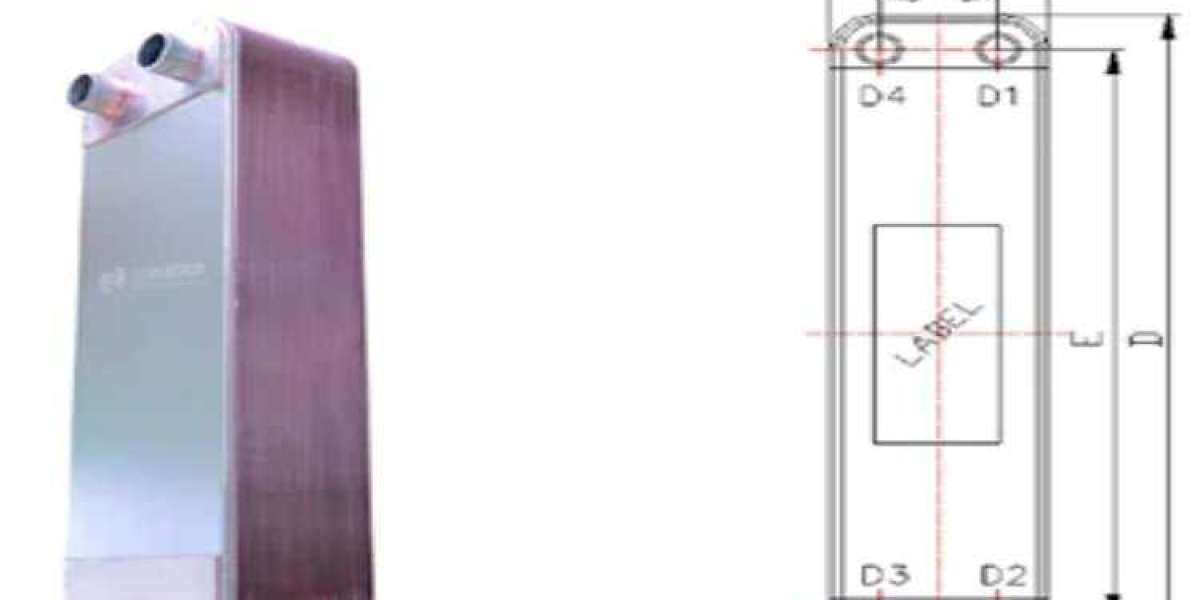

Wide channel plate heat exchangers have wider plate flow channels and deeper corrugation depths. Due to the unique corrugated form of the plates, it is also known as a free flow plate heat exchanger.

product features:

The wide channel plate heat exchanger is specially developed for the heat exchange conditions of various solids, crystals, fibers, pulpy substances or viscous media that are easy to block. Due to the special design of the plate, the wide gap channel is smooth. There are no metal contact points between the plates, and the fluid flows smoothly, without stagnation, dead zone, and blockage. The width of the flow channel between the plates can reach 6-16mm to ensure that the medium can pass through without pressure. The pressure loss is small and the fluid distribution is uniform. Even if the pulp fiber length in the juice reaches 10mm and the content reaches 10%, it can run smoothly.

Application range:

Mainly used in wastewater waste heat recovery, light industry brewing, sugar refining, food and beverage, printing and dyeing, electric power, metallurgy, medicine, textile, papermaking and other technological processes to deal with heat transfer of materials. Mash, granular media and viscous media.

In the coal industry, coal washing wastewater contains solid particles such as coal washing powder, sand, and clay. Its turbidity is high, and it has both the properties of suspension and colloid.

Mine water contains pulverized coal, mud water, minerals, etc. Compared with coal washing water, the content of solid particles is less. Wide-channel plate heat exchangers can be used as coal washing water heat exchangers and mine water heat exchangers, effectively utilizing waste heat energy and avoiding environmental pollution.

Structure and use

The wide channel plate heat exchanger belongs to the partition wall heat exchanger. The plate type adopts a unique rough corrugated wide gap channel structure design, and the outer contour of the plate is basically composed of horizontal corrugations. It fills the special medium working conditions that the chevron-shaped corrugation cannot be applied, and has the high heat transfer performance that the traditional tubular heat exchanger does not have. When designing and selecting a wide-channel plate heat exchanger, it is necessary to understand some physical parameters of the heat exchange medium, such as temperature, flow rate, medium source, whether it contains particles or fibers, etc. The size or length of impurities in the medium, whether it contains corrosive substances, etc., ensure that the design and selection of the wide-channel plate heat exchanger is more reasonable.

If the particle size in the medium is less than 30mm, or contains long fibers/straw, an ultra-wide channel intelligent heat exchange system can be selected, which can be used for cold and heat exchange processes such as organic fertilizer, breeding, slaughtering, solid-liquid waste treatment, and biological fermentation.

Jiangsu Yuanzhuo Equipment Manufacturing Co., Ltd. is a professional manufacturer of plate heat exchangers. Plate heat exchangers are widely used. We have Brazed Plate Heat Exchangers and Gasketed Plate Heat Exchangers. If you are interested in plate heat exchangers, please feel free to contact us.